Like a Virgin…Plastic

What Extended Producer Responsibility is and how it’s pushing the circular agenda

Virgin plastics are the main material source for packaging. Packaging that, the vast majority of the time, ends up in landfills and doesn’t get reused. Not to mention other packaging materials like paper, cardboard, glass, etc. Or the 40 million tons of textile waste that’s created annually. It’s safe to say, we have a waste issue on our hands—the vast majority of it “virgin” materials. Virgin materials are made directly from natural resources and not from existing materials. Incorporating post-consumer and post-manufacturing waste into the early stages of your supply chain (i.e. moving away from virgin materials) is circularity.

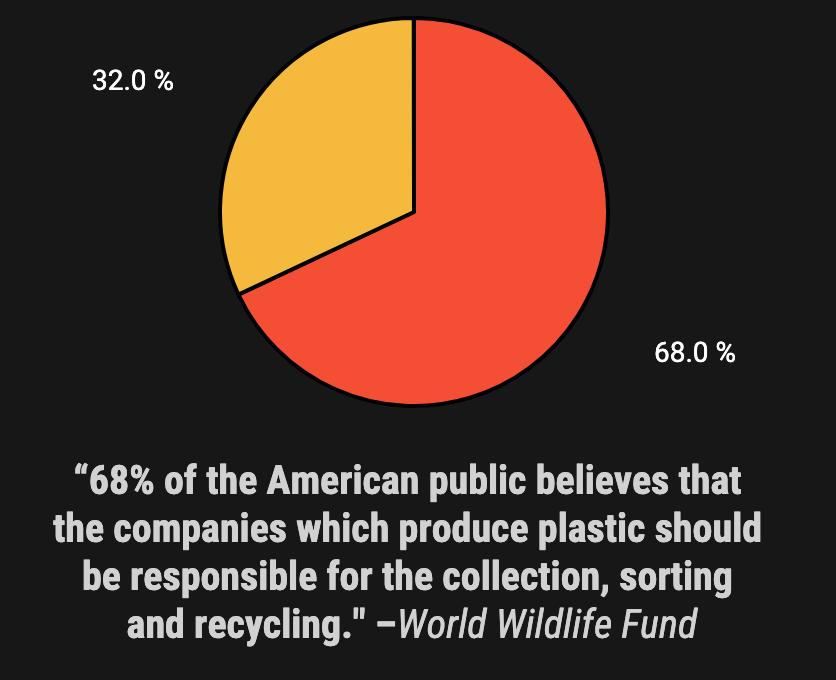

With recycling processes historically falling on the shoulders of local governments, businesses weren’t being forced to confront the reality of what happens to their waste after it leaves their facilities. Extended Producer Responsibility legislation is trying to change that. According to the OECD, “Extended Producer Responsibility (EPR) is a policy approach under which producers are given a significant responsibility – financial and/or physical – for the treatment or disposal of post-consumer products.” It’s the only proven way to incentivize recycling and increase the amount of recycled materials in new products, and while they’ve been adopted in Europe widely over the last two decades, they’re recently picking up traction in the US.

“Yet in most cases, producers have no stake in the success of recycling programs. Recycling programs are managed and financed primarily at the local level, either funded by taxpayers or by user fees on households. However, local governments cannot control how products are made or how easy they are to recycle, and are faced with ever-increasing expenses to manage these materials.”

Ecocycle.org

With the onus put on individual companies to recycle their own products and waste, there’s even more incentive to make the products more easily recyclable and try to limit waste in the first place. The best way to cut costs while avoiding EPR taxes is to incorporate that waste back into the supply chain, where possible.

The OECD similarly argues that, “assigning such responsibility could in principle provide incentives to prevent wastes at the source, promote product design for the environment and support the achievement of public recycling and materials management goals.” By enforcing corporate accountability at the end of the supply chain, by focusing on waste, governments are effectively promoting circularity across the entire supply chain. It’s in a business’ best interest to utilize the materials they already have, thereby cutting costs at the sourcing and recycling level.

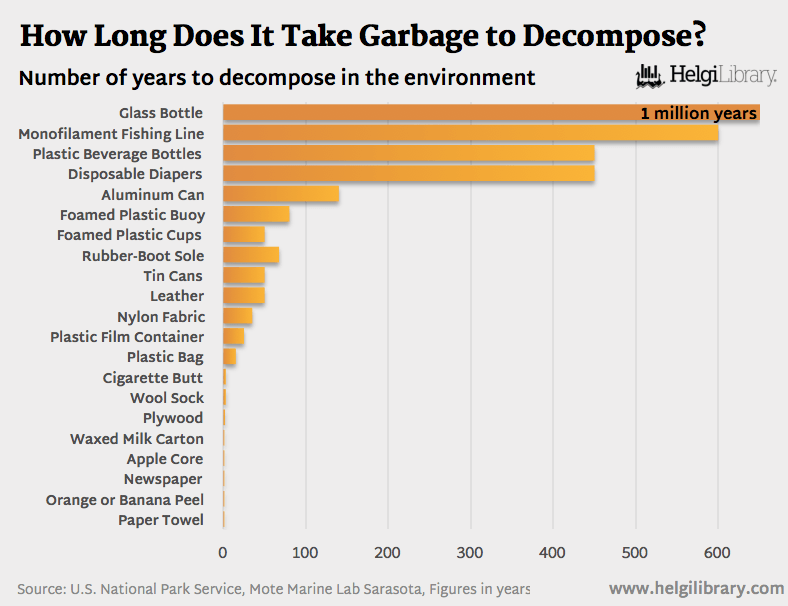

When you look at the staggering difference in the amount of time it takes for plastic waste to decompose versus natural materials like paper, it makes sense that laws are being put in place to try to reduce the amount of virgin plastic and other harmful materials that end up in our landfills. How likely is this to affect your business? Let’s take a closer look.

FORCING ACCOUNTABILITY

How Extended Producer Responsibility incentivizes recycling

As we mentioned earlier, “since product manufacturers and brand owners control how a product is designed and manufactured, they have the most direct influence on whether their products and packaging can be recycled. Yet in most cases, producers have no stake in the success of recycling programs” (Ecocycle.org). Extended Producer Responsibility laws streamline the number of hands material waste has to pass through, and forces businesses to confront their waste problems. Because of their proven success, EPR laws are gaining steam in the U.S.

“In the U.S., there were over 115 producer responsibility policies across 33 states in 2019, a tremendous increase from fewer than 10 policies in 2001” (Ecocycle.org). Now the focus is turning to packaging—a huge driver of waste.

“In 2021 the states of Maine and Oregon became the first U.S. states to adopt producer responsibility laws for packaging” (Ecocycle.org). This is just the tip of the iceberg. “In 2022 similar legislation will likely be considered by California, Colorado, Connecticut, Delaware, Illinois, Maryland, Massachusetts, New Hampshire, New Jersey, New York, Pennsylvania, Washington, and Vermont” (Waste360).

The spread of EPR legislation increases corporate accountability for their role in the world’s waste problem by forcing them to front the financial burden of recycling their own waste, and oftentimes includes financial repercussions, like paying additional taxes, for not complying.

Measure for More

How Vi3’s tools enable smarter recycling

There is a short-term solution and a long-term solution to the increasing prevalence of EPR legislation. The short-term solution requires you to manage the waste you currently produce through recycling measures. The long-term solution requires a deep dive into your entire supply chain, honing in on where you can eliminate virgin plastics, reuse materials and incorporate waste into new products, and recycle what doesn’t get used. While the latter requires upfront investment of time and money, its payout long-term is significant.

“Those investments, however, can show a return quite quickly. According to Gartner, the circular economy is a model that separates the ability to achieve economic growth from the consumption of natural resources. Circular models encourage continuous reuse of materials to minimize waste and natural resource consumption. Many companies using this model are already profiting.”

Forbes