From Returns to Repurposing

On the multifaceted nature of reverse logistics

Within supply chains, there’s understandably a lot of emphasis on forward movement—how raw materials end up as products in consumers’ hands. But what about all the products that make it to consumers’ hands, only to be returned, either because of a product defect or someone decides they don’t want it anymore? Now we’re talking about reverse logistics, or the process that The Atlantic describes as, “getting unwanted items back from consumers and figuring out what to do with them”, which, turns out, is an extremely “time- and labor-intensive” process. So much so that most returns don’t make it back into the forward-moving half of the supply chain, and have little likelihood of ending up in a consumer’s hands again.

With e-commerce return estimates sitting at about “30% of purchases…and about half of all clothing”, the reverse logistics process is one that has a big impact on your company (LA Times). Unfortunately, it’s also a process that’s notoriously disorganized and costly. Products get sent back to distribution warehouses, where they must be evaluated for damage and then sorted. After return shipping costs and the manual labor required to validate returns alone, it often ends up hurting a company more to process them. Research has shown that “$1 million in returns can potentially erode $500,000 in profits, prompting many major retailers to simply allow shoppers to keep merchandise rather than process a costly return” (Forbes).

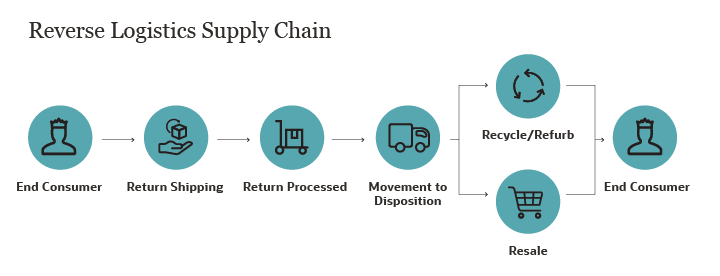

But it’s important to recognize that the reverse logistics process incorporates more than just returns—it includes “all operations related to the reuse of products and materials,” which “can include all recycling, reclamation of raw materials, refurbishment, and reselling of items that have been restocked” (GLOBALTRANZ). By honing into the many facets of reverse logistics, and implementing more organized processes around technology and data, you can turn your reverse logistics chain into something that helps the environment and your company’s profits.

One Man’s Trash

Understanding the impact of poor reverse logistics

According to an article in the LA Times, a Canadian investigation around Amazon returns showed that of “12 items returned, only four had been resold” and “the rest were still in transit months after being returned. At least one, a new backpack, was found in a landfill”. This summer, employee reports showed that Amazon destroys hundreds of thousands of products a week, many of them returns (Business Insider). These examples are exempletive of how reverse logistics processes can be wasteful of both time and materials.

There are so many points in an object’s life where it could go to the trash heap instead of to a person who will use it, and once it’s off the books—especially if it’s out of the country—American retailers are no longer keeping track. These practices are essentially unregulated; companies do whatever they deem most profitable.”

The Atlantic

A large part of the problem is that consumers don’t know just how costly their returns are. This shows up in the discrepancy between the number of consumers who want to support sustainable companies—the majority of “Americans under 40 say that they’d happily pay more to patronize businesses that aren’t wasteful or harmful to the environment”—and how many of those same consumers shop and return online to avoid the hassle of shopping in stores (The Atlantic). Most consumers happily shop at locations that provide fast shipping and free returns because it’s a better customer experience, and allows people to shop online more freely—ordering multiple sizes of a single item with the intention to skip the dressing room, try on at home, and return the ones that don’t work out.

So how can businesses cut down on waste throughout a process that’s costly by nature? The answer is threefold:

- Educate consumers on more sustainable shopping strategies

- Shopping in-store if possible (eliminates shipping costs and the need to order multiple sizes)

- Incorporating detailed size guides on your online stores, to help customers find their best fit

- Making return policies clear and sharing information around recycling programs

- Incorporate supply chain traceability with blockchain technology

- Track product life cycle in its entirety

- Identify areas where certain products, distribution centers, etc. could be more sustainable

- Incorporate consumer accounts into the sales process, so that repeat returners can be identified

- Utilize technology to implement circular business practices

- Utilize materials from returned products to recycle into new products

- Refurbish products for resale via new channels

- Resell unused products via your regular channels

While consumers want to buy from companies with generous returns policies, they also want to support businesses who are clear about how they’re helping the planet. “By embracing reverse logistics strategies—including returns management, product repair and refurbishment, recycling of goods and materials, and proper disposal of materials from unwanted goods—companies can boost sustainability while also cutting costs and extending a product’s shelf life” (Forbes). By incorporating recycling and refurbishment programs into your reverse logistics process, you’ll serve a larger segment of the consumer population, cut down on raw material consumption, and make huge strides in your sustainable business practices.

Back to the Future

How to incorporate circularity into your reverse logistics with Vi3

Making strides in these areas can feel daunting, which is why you need systems in place to trace products, authenticate them, and educate consumers. Utilizing technology like blockchain will ensure your data is never lost and will provide a secure ledger for you to trace the life cycle of your products—enabling you to understand where you currently fall short, and how you can grow.

With Vi3’s suite of tools, you can track your products end to end. V Source gives you unprecedented insight into your supply chain, giving you a view into the post-production life cycle of your product. With V Connect, you’re able to pinpoint consumer engagement with the product. Our technology allows you to pinpoint when a product’s life cycle stops at the consumer, and when they are returned to you for repurposing, recycling, or resale.

With data at your fingertips, you can track your own progress on circular measures through reverse logistics, and report out on these to consumers. This loop of transparency between you and your products, and you and your consumers, will be your best marketing tool—pulling in the new generation of conscious consumers and ensuring your brand stays relevant in today’s market. And hey, it’s not a bad thing that you’ll save resources, and the planet, along the way.